Waterproof Circular Connector and Customized Cable, Pins, Molding

Exploring the Versatility of Waterproof Circular and Outdoor Connectors and Molded Cable Assemblies

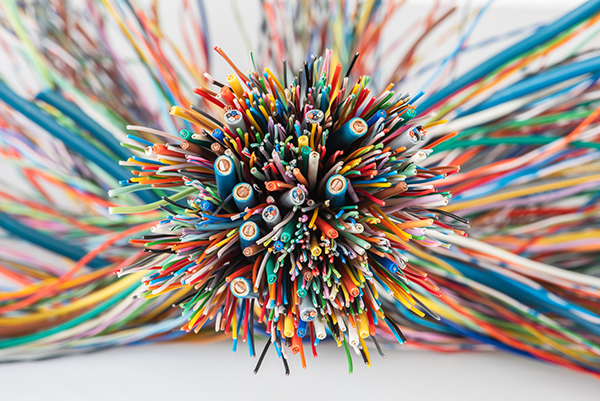

In today's ever-evolving technological landscape, the demand for resilient and weather-resistant connectivity solutions has reached unprecedented levels. Weatherproof connectors, alongside their cable, stand as pillars of reliability across multifaceted applications and industries.

Quality Waterproof Circular Connectors: Resilience and Precision

The technological marvel of waterproof connectors has paved the way for transformative connectivity solutions. These connectors, certified with IP67, IP68, and even the stringent IP69k ratings, serve as beacons of resilience in the face of harsh environmental conditions. Their circular design, coupled with stringent IP ratings, provides an impenetrable shield against moisture, dust, and various external elements, ensuring uninterrupted data and power transmission. Within marine industries, where exposure to water and saline environments is constant, these IP-rated connectors over-molded with cables play a pivotal role in maintaining secure.

Navigating Through the Elements

Circular waterproof connectors, including the robust waterproof bulkhead connectors, are engineered to withstand extreme weather variations, making them indispensable in outdoor installations and infrastructures. The IP-rated sealing of these connectors ensures steadfast performance even amidst challenging climates, including temperature fluctuations, humidity, and exposure to UV radiation. Telecommunication networks, lighting systems, new energy and renewable energy installations rely on these connectors to maintain consistent, regardless of weather adversities.

Weatherproof Connectors: Unwavering Performance in Diverse Conditions

Weatherproof connectors, bearing IP67 and IP68 ratings, champion the cause of reliable connectivity amidst varying weather conditions. Their circular design, coupled with superior shielding capabilities, ensures secure connections that remain unaffected by moisture ingress or temperature changes. In aerospace, industrial automation, and telecommunications sectors, these weatherproof connectors uphold their reputation by facilitating seamless data transmission in environments where precision and reliability are non-negotiable.

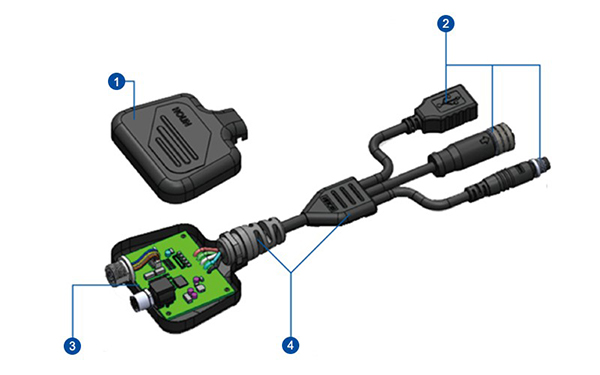

Molded Cable Connector: The Backbone of Connectivity

The integration of waterproof connectors into customized extension circular connector cable reinforces the resilience and dependability of connectivity solutions. These assemblies, meticulously designed and engineered to adhere to IP-rated specifications, bridge connectivity challenges across a multitude of applications. Underground installations, outside equipment, and complex machinery rely on these molded cables and connectors to maintain optimal performance, safeguarding data and power transmission in environments where adherence to IP-rated standards is imperative. We are not only make cable waterproof connector, but also make waterproof RJ45, USB, HDMI, BNC and SIM card connectors IP68.

Circular Connectors Are Used In Industrial Applications

The applications of IP-rated waterproof connectors are designed for diverse industries with varying environmental demands. In marine and offshore settings, where exposure to moisture and saline environments is constant, these connectors ensure continuous communication and power distribution. In lighting systems, they uphold reliable connections despite weather fluctuations, ensuring consistent performance. Moreover, in renewable energy installations, they play a crucial role in maintaining the operational integrity of essential components, embodying adaptability across IP-rated environments.

Conclusion: The Resilience of Connectivity Solutions

In conclusion, the applications of IP-rated waterproof, outdoor, and weatherproof circular plastic connectors, and cable assemblies are designed for harsh industrial environment. Their resilience, versatility, and unwavering commitment to adhering to IP-rated specifications make them indispensable components in ensuring consistent, secure, and weather-resistant connectivity solutions across various environments and industries.

Frequently Asked Questions (FAQs)

Is HOLIN a Professional Manufacturer

HOLIN has 20 years of manufacturing and quality control experience in Taiwan, specializing in waterproof connector and molded cable. We prioritize tailored services, crafting solutions that meet our customers' specific needs. We're not just manufacturers; we're enablers, transforming our customers' ideas into reality.

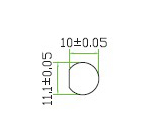

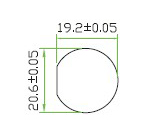

What size of Circular Waterproof Connectors HOLIN povide?

| Circular Panel Mounting Connectors' Panel Hole Dimension (unit : mm) | |||||

|---|---|---|---|---|---|

| A size (Mini) | B size (Standard) | C size (Middle) | D size (Large) | E size (Macro) | P size (C16) |

|

|

|

|

|

|

What are number of pins and current rated of HOLIN Circular Series?

| Current Rated per Pin | 2A | 5A | 10A | 20A | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of pins | 4 | 5 | 6 | 10 | 12 | 18 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 2 | 3 | 4 | 5 | 6 | 7 | 2 | 3 | 4 | 5 | 6 | 7 | |

| Connector Size | A | A | A | B | B | C | A | A,B | A,B | B | B | B | B | B | C | C | C | C | B | B | B,C,P | C | C | P | C,D | C,D | C,D | D | D | D |

We provide wire range of voltage: 12V, 48V, 50V, 125V, 250V, 300V, 600V and 630V conncectors.

What customized service HOLIN provide?

Cable:

At HOLIN, we offer customized cables tailored to suit your specific environmental requirements. You are able to define the cable you need.

Ex: flexibility, freezing resistance, rodent protection, seawater resistance, UV resistance, oil resistance, UL cable, Cat5e, Cat6 and more."

Pins can be customized:

You are able to define pin's length, material, diameter, surface treatment.

Ex. For receptacle connectors, the wire soldering pin end can be bucket, cup, flat or others. The PCB dip pins dimension can be customized to suit your Print circuit board layout.

We have 2 pins, 3 pins, 4 pins, 5 pins, 6 pins, 7 pins , 8 pins, 9 pins, 11 pins, 12 pins, 13 pins, 14 pins, 15 pins, 16 pins, 17 pins, 18 pins, 31 pins, 37 pins in our standard product line of Circular Waterproof Connectors.

Connector:

You are able to define Hybrid pins on our existing connectors if thre is no combination fit your requirement.

Or we are able to create a new customized connector for you.

Molding:

We are not only make circular connector series, but also make strain relief, other connectors, sensor more molded with cable.